Harness Augmented and Virtual Reality Technologies

Transforming training, maintenance, and production processes through the power of immersive technology.

Revolutionising Workforce Development with AR/VR Technology

AR/VR is reshaping how we train, upskill and empower the modern workforce. Through immersive simulations and interactive environments, employees can safely master complex tasks, accelerate learning, and build confidence — all without disrupting live operations. Whether it’s onboarding new staff or upskilling experienced technicians, AR/VR transforms workforce development into an engaging, efficient, and future-ready experience.

Transform Your Maintenance with Cutting-Edge AR Technology for Enhanced Efficiency

AR is revolutionising maintenance processes by providing real-time, interactive guidance. This technology enables technicians to perform repairs and troubleshooting with unprecedented accuracy and speed.

Efficient Maintenance

Efficient Training

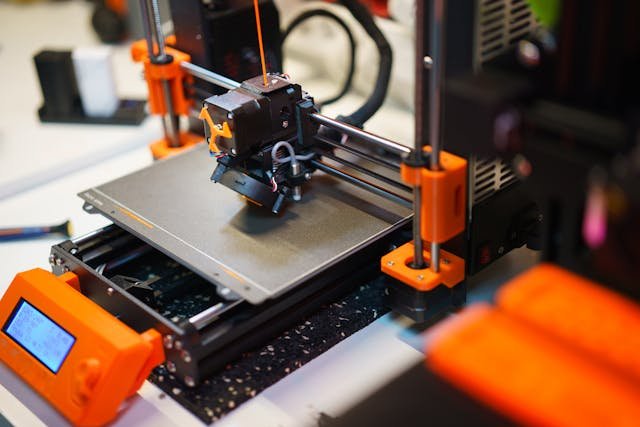

Enhancing Efficiency and Insight with AR/VR in Manufacturing

Experience the future of manufacturing with immersive AR/VR technologies. Visualise production lines and streamline operations like never before.

Optimised Production

Visualise and simulate production processes in VR to identify bottlenecks and optimise workflows.

Enhanced Training

FAQs

Discover answers to common questions about AR/VR in manufacturing and its practical applications.

Implementation costs for AR/VR can vary widely depending on the scale of the project. Typically, you should budget for hardware, software, and training expenses. A thorough cost analysis is essential to determine the best approach for your business.

AR/VR systems are designed to integrate with various existing manufacturing systems. Compatibility often hinges on the specific technologies in use. Consulting with your technology provider can help ensure seamless integration. If you are unsure on how best to do this – Pioneers Victoria is here to help!

These technologies streamline processes, speed up prototyping, and improve employee training through immersive, hands-on experiences. They also support faster and more accurate maintenance, often with remote expert guidance, and ultimately lead to significant cost efficiencies over time. AR/VR is helping manufacturers experience, refine, and future-proof their operations like never before.

F.A.Q.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Transform Your Manufacturing Process

Ready to explore how AR/VR can revolutionise your manufacturing? Get in touch with us!