Automation Done Right (& Wrong)!

Don’t automate for the sake of it — automate what matters.

Transforming Manufacturing with PROVEN Technologies

In today’s era of rapid technological change, manufacturers are bombarded with promises about what AI could do—optimise production lines, predict machine failures, automate decision-making. While these possibilities are exciting, relying too heavily on “black box” AI models or untested tech can actually undermine efficiency, safety, and trust in your operations.

Instead, leveraging proven technologies—those that are transparent, reliable, and grounded in well-tested engineering principles—should form the foundation of any smart manufacturing strategy. These systems can absolutely integrate AI, but that AI must augment human expertise and validated systems, not replace them entirely.

Why Proven Technologies Matter: A Cautionary Tale from Aviation (737 MAX)

A well-documented aviation incident involved an automated stabilisation system that relied on a single sensor and lacked sufficient pilot training and manual override options. The system’s failure contributed to multiple accidents and raised global concerns about over-reliance on automation without transparency or safeguards.

Automation Done Right

Start with Proven, Purpose-Driven Technology

Begin with technologies that are tested, reliable, and solve a real operational pain point — not just what’s trendy. Whether it’s predictive maintenance, real-time monitoring, or machine vision, anchor automation in business value and user needs.

Design with Human and System Collaboration in Mind

Design systems that augment, not replace, human expertise. Build automation that offers transparency, explainability, and manual overrides. Empower operators and engineers with tools they can understand and trust.

Test, Validate, Scale

Start small, measure everything, and tweak until it works. Only scale when it’s field-tested and battle-hardened — because in manufacturing, capital “investment” doesn’t just cost money — it puts your reputation, operations, and future on at risk.

Automation with Pioneers Victoria

Our Core Technology Stack

Our core technology stack combines Industrial IoT sensors with Ditigal Twins, Edge Computing, and Augmented Reality to modernise manufacturing—turning data into action, in real time, on the factory floor.

It’s automation done right: practical, proven, and built for results.

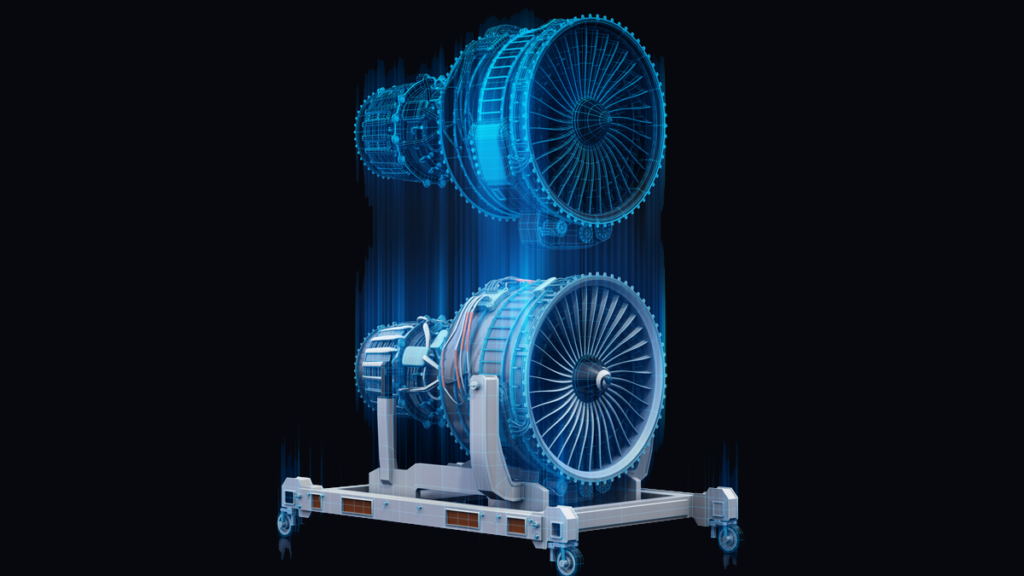

Industrial IoT Sensors &

the Digital Twin

We connect physical machines to the digital world using smart IoT sensors, enabling real-time monitoring, predictive maintenance, and performance optimisation. Every data point feeds into a dynamic digital twin — a virtual replica of your operations — for smarter decision-making and simulation at scale.

Edge Computing &

Machine Learning

We combine the power of edge computing and the cloud to deliver real-time insights and long-term intelligence. Critical decisions happen instantly on the factory floor, while the cloud supports deeper analysis, optimisation, and system-wide learning. From anomaly detection to performance tuning — it’s fast, efficient, and built for automation done right.

Knowledge Embedded, Yet Effortlessly Shared

We embed operational knowledge directly into the system — so it stays put, even as teams evolve. Using technologies like augmented reality, knowledge is delivered exactly where and when it’s needed — overlaid onto machines, workflows, and tasks in real time. It’s no longer buried in manuals or lost in handovers. Instead, it’s visual, accessible, and instantly usable. The result? Greater consistency, faster onboarding, and a workforce empowered by built-in expertise.

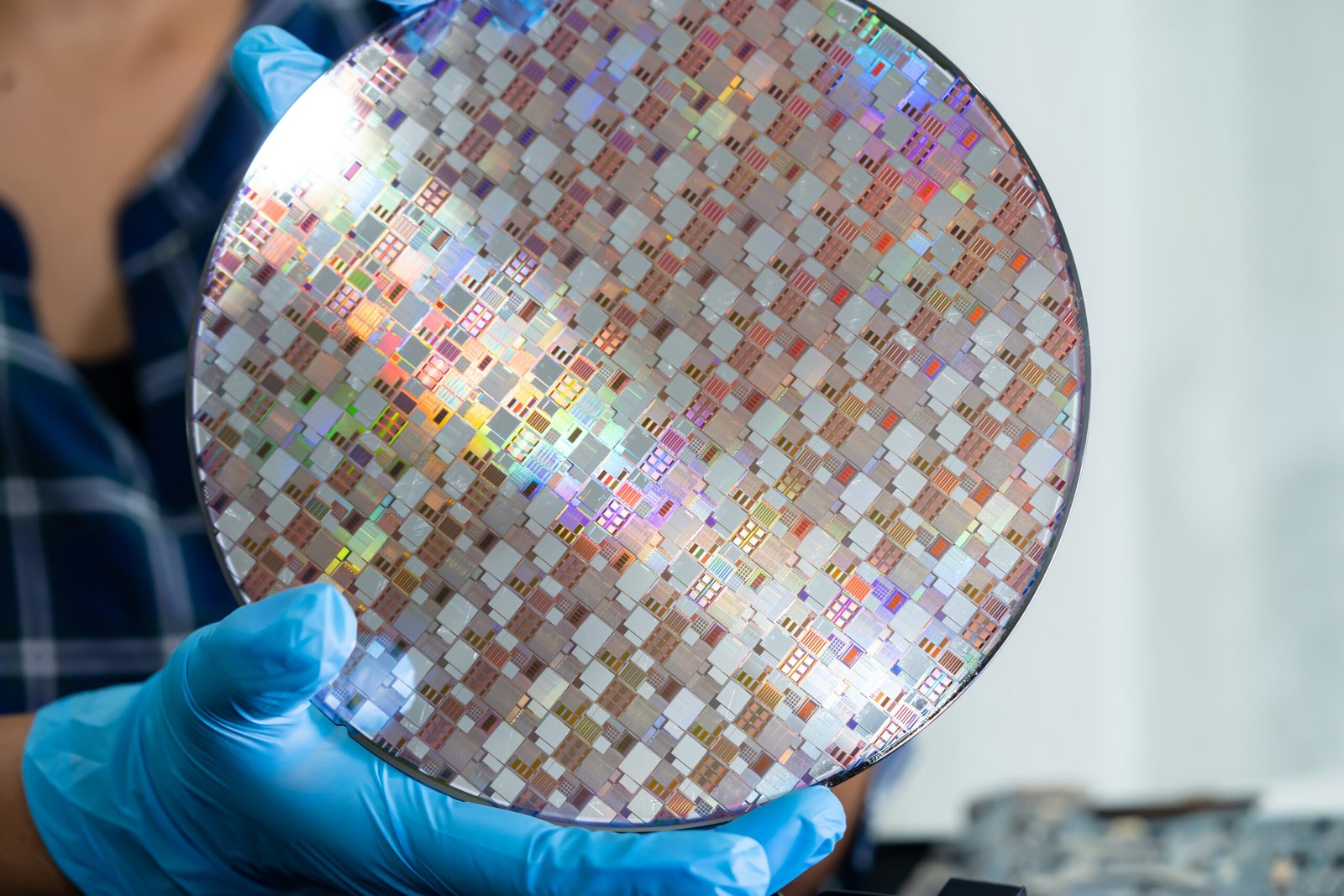

Automation Done Right - TSMC

How a SINGLE company makes up

5% of a Country's Entire GDP

Taiwan Semiconductor Manufacturing Company (TSMC) is a global leader in smart manufacturing. By strategically integrating automation, they increased production efficiency by 20% and cut defect rates to nearly zero.

What TSMC Did Right:

Phased Rollout: Automation was introduced gradually, allowing time for testing and refinement.

Human-Centred Design: Systems were built to support — not replace — workers, combining machine precision with human judgment.

Continuous Optimisation: Real-time monitoring enabled constant improvements and fast adjustments.

TSMC proves that when automation is implemented with purpose and precision, it delivers measurable gains without compromising people or quality.